There are many reflective, shiny and/or mirrored (RSM substrates) surfaces that you may wish to use with your UV printer for personalization and/or decoration. These RSM substrates include glass and crystal products. Printing to these RSM substrates presents a specific type of challenge. You must avoid allowing the UV light to bounce back into the print head. The light can cure the inks in the nozzles and on the nozzle plate, which can cause serious damage that can significantly decrease the life of your print head. Following the simple procedures outlined in this Tech Tip will help you minimize this risk.

- The only time you should mount an RSM substrate onto the bed of your Direct Jet UV printer is to send the table to print home, adjust the head height, and print. NEVER have the RSM substrate mounted on the table with the head above the recommended printing height, including during nozzle checks and/or filling of cartridges, etc.

- Only print onto RSM substrates that are flat. For example, if you are attempting to print to mirrored vinyl, you first must attach the mirrored vinyl to a flat piece of material.

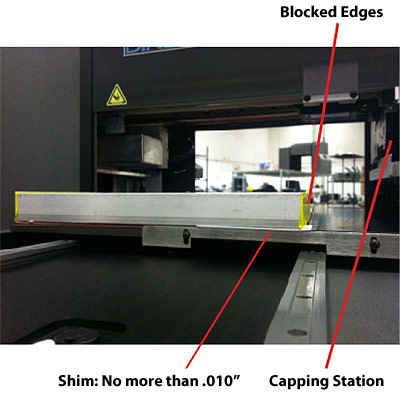

- Angle your RSM substrate slightly so that it slopes downhill away from the capping station (see diagram above). This will cause any refracted light to be directed away from the head.

- When printing onto an RSM substrate that has a multi-faceted face (such as a crystal award or like the cut on a diamond), use masking or light-blocking tape on all non-printing areas.

- When printing onto RSM substrates, perform regular nozzle checks to ensure nozzle health is correct. If nozzles are missing, perform head cleans to correct missing nozzles. If ink is curing on the nozzle plate or in the nozzles, it is important to clear it out of the nozzles or off the plate so it doesn't continue to attract other stray ink droplets.

- When printing onto RSM substrates or, in general, when printing more than 4 hours in a day, always end the day/shift with a nozzle check to ensure that all nozzles are correct before powering down the printer. If nozzles are missing, perform head cleans to correct missing nozzles.

- Never manufacture jigs and/or fixtures out of RSM materials. When using acrylic, DCS recommends colored acrylic. When metal or aluminum is used, DCS recommends painting and/or black anodizing any reflective areas, including the cavities.

It is extremely important that these procedures be followed whenever printing to RSM substrates. The damage caused by the UV light reflecting or refracting back into the print head is expensive, but it is avoidable by following these steps and taking proper care of your Direct Jet printer. Contact DCS Tech Support at techsupport@directcolorsystems.com or 860-829-1027 if you have any questions.