860-829-2244

With nearly 50 different print modes to choose from in Color Byte RIP 9, understanding when to use certain print modes and settings will be vital to achieving the desired output. The key is finding a balance between production time and quality. Below are application samples that were printed on DCS Direct Jet UV LED printers. These examples represent a diverse range of substrates, production time requirements, adhesion and quality expectations.

3D Objects

- Substrate: Golf Ball

- Print Mode: Photo Color Only Quality

- Suggested Setting Change: None

- Description: DCS UV printers allow the user to print large diameters on three-dimensional objects. This particular print mode puts down larger dots, which have the ability to fall further after being jetted from the print head. The mode also prints in Uni-Directional, which yields better accuracy in terms of dot placement. Most users who print golf balls are doing so in significant quantities. Therefore, production time plays a big role. This print mode keeps a good balance between production time and quality of print.

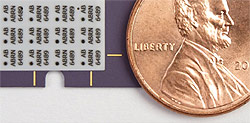

Fine-Point Text

- Substrate: Ceramic

- Print Mode: Color Only Super High Quality

- Suggested Setting Change: Change rendering intents to print Spot Black

- Description: When printing small text, the most important thing to do is use a print mode that is Uni-Directional. This will allow for more accurate dot placement and faster cure, which will eliminate any bleeding on the text. Also, using the least amount of ink possible while still maintaining saturation is important. For small black text, use Spot Black instead of process.

High-Speed Printing

- Substrate: ABS plastic

- Print Mode: Color Only High Speed

- Suggested Setting Change: None

- Description: Many times, a small graphic that is printed on white promotional products does not need to output at a very high quality. These jobs are usually run in mass quantities and are used by companies as giveaways. In this case, try saving time by using a high-speed print mode. One concern with faster speeds is adhesion; however, UV ink adheres extremely well to ABS plastic, even at high speeds.

Industrial Printing and Adhesion

- Substrate: Smooth Powder-Coated Aluminum

- Print Mode: Finish with White with Color Production Speed

- Suggested Setting Change: Try using smaller dots to decrease ink volume

- Description: Industrial applications require a certain level of adhesion to be practical. UV inks, while extremely versatile, do not adhere to all surfaces. However, there are print modes available to help with adhesion to these substrates. Clear ink is going to bond the best to these hard-to-adhere-to substrates, so start with this by using a finish with white with color print mode. Try limiting the ink volume so there is not a thick layer on the object that can be picked off with a fingernail.

Photograph

- Substrate: Wooden Plaque

- Print Mode: Photo White with Color High Quality

- Suggested Setting Change: Increase the volume of white ink

- Description: When a little time can be sacrificed for high-quality images, try using the high-quality photo modes. These are special print modes that have unique settings to output photographs that have a consistently smooth attribute. Increase the ratio of large to small dots or adjust the separation curves for the white channels to get a more opaque white prime. This particular photograph is on dark wood, and having an opaque white primer will help boost the color.

Texture Printing and Fine Detail

- Substrate: Plastic Phone Case

- Print Mode: Texture Normal

- Suggested Setting Change: Change to Uni-Directional

- Description: By default, the Texture Normal print mode is 2x faster than the Texture Max and Extreme print modes. However, all are at Bi-Directional, which makes it difficult to print fine detail. Try changing the Texture Normal Print mode to Uni-Directional, which will give you the same output time as Texture Max and Extreme but will increase the quality of your texture prints.